Annual Open House 2024

November 2024

The Annual FANUC UK Open House offers visitors an all access pass to the UK facility of this global leader.

Hosted at our UK headquarters at Ansty Park, Coventry, the Open House hosts a series of talks, panel discussions and interviews with some of the leading lights in British industry, tackling the most pressing issues facing UK manufacturers such as:

- Upskilling your workforce

- The outlook of automation in UK manufacturing

- Sustainable manufacturing and the circular economy

We also welcome an extensive array of exhibitors and partners from the across the world of automation.

I look forward to seeing you all this November!

Tom Bouchier – Managing Director, FANUC UK

What’s on?

The Annual FANUC UK Open House will take place November 2024.

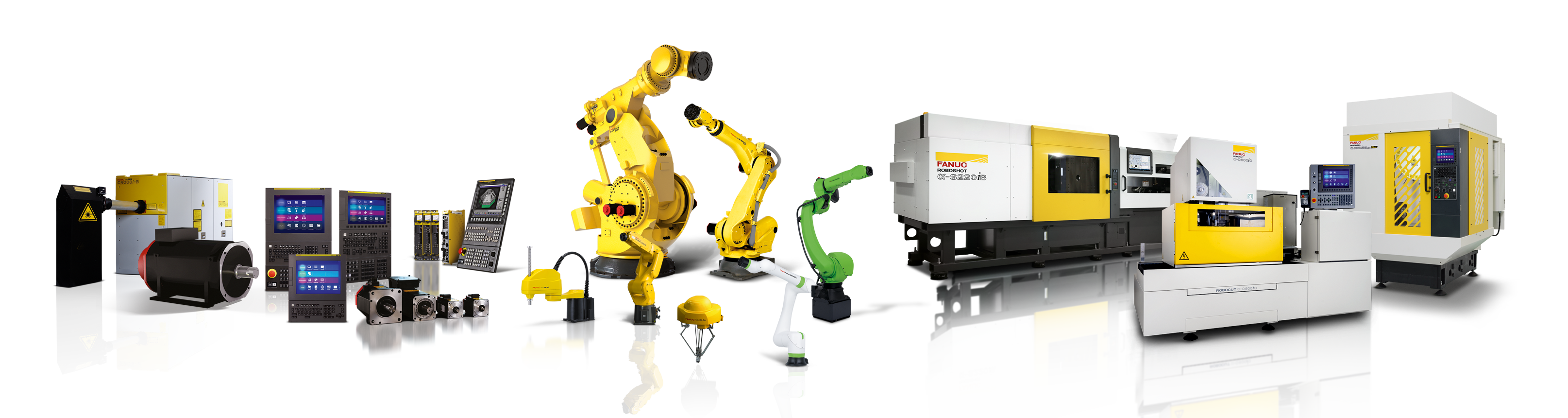

Visitors will be able to see FANUC’s latest technology, including its world-leading range in industrial and collaborative robots, machining centres and plastic injection moulding machines, alongside a range of guest exhibitors displaying a wide variety of automation applications.

Expect hands on robot training, live demonstrations and insights from some of the leading lights in British industry.

Take a look at our automation cells

Visitors to Open House will be able to experience a broad range of real-world industrial automation systems, condensed into compact demonstration cells.

Register Now!

Visit the FANUC UK OPEN HOUSE 2024

Register now to:

- Experience – in person – the latest developments from across the world of industrial automation.

- Listen to the leading lights of the industry give their thoughts on the most pressing issues affecting UK manufacturers.

- Speak with industrial automation experts from many different organisations.

- Learn how FANUC can help you on your own automation journey.

Livestream

Watch the event live

How to find us

FANUC is located at Ansty Business Park.

Address: Sapphire Way, Ansty Business Park, CV7 9DR